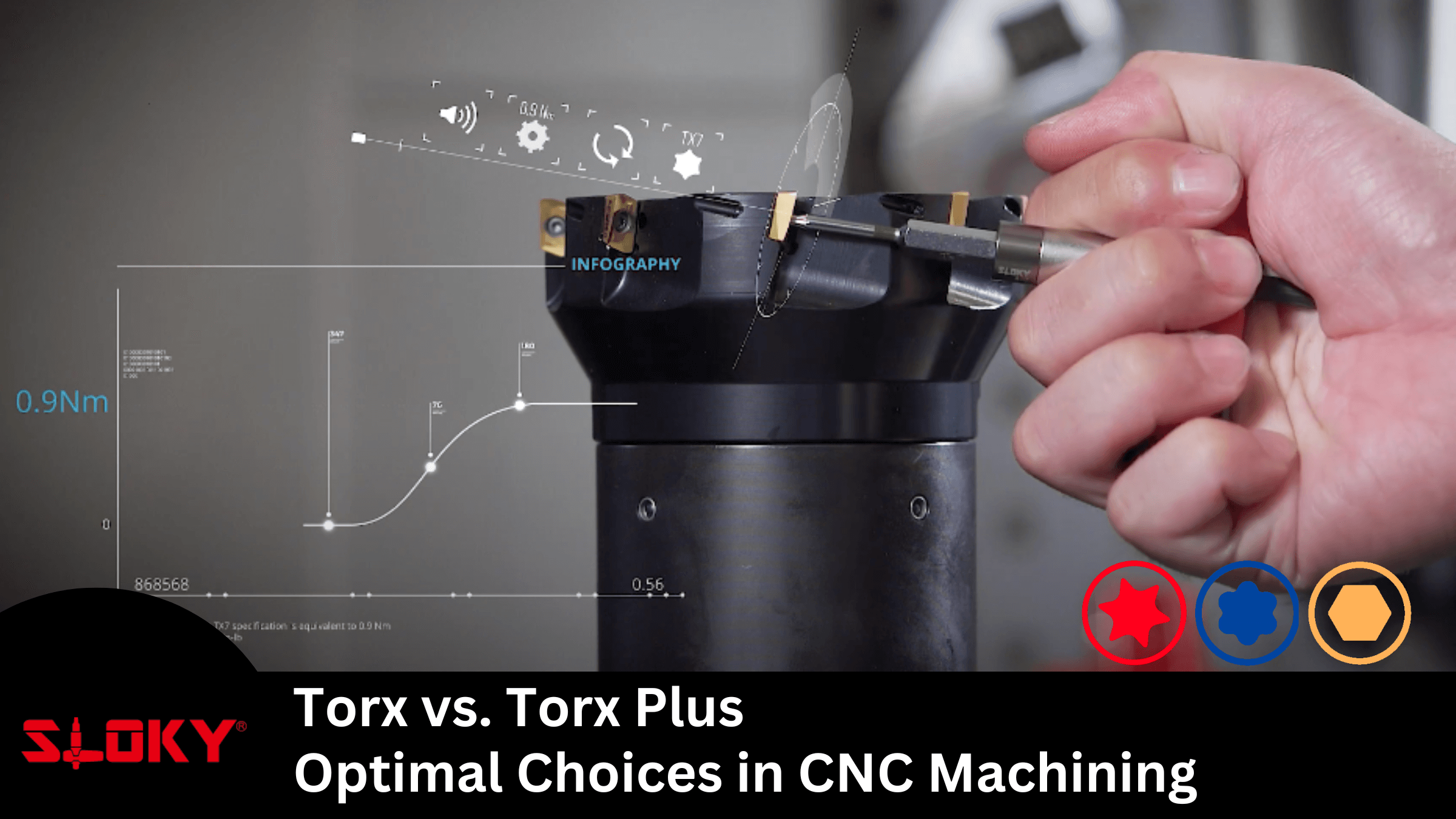

In the precision-driven field of CNC machining, tool selection significantly impacts efficiency and quality. Torx and Torx Plus fasteners are favored for their exceptional performance in high-torque applications, offering precision and durability crucial in this field.

Why Is There So Many Different Types of Bits

The wide variety of bits available caters to the diverse requirements of modern machining and manufacturing. Different materials and processes require bits that deliver precision without compromising strength or causing damage. Torx and Torx Plus have been engineered to meet these specific needs, providing tailored solutions for various industrial applications.

Why Are Torx and Torx Plus Common in CNC Machining

In CNC machining, Torx and Torx Plus are particularly valued for their superior torque transmission capabilities and resistance to slippage. This capability is crucial when working with metals and other hard materials where precision and tool integrity are paramount. Their unique designs minimize wear and tear on both the bit and fastener, extending tool life and reducing maintenance.

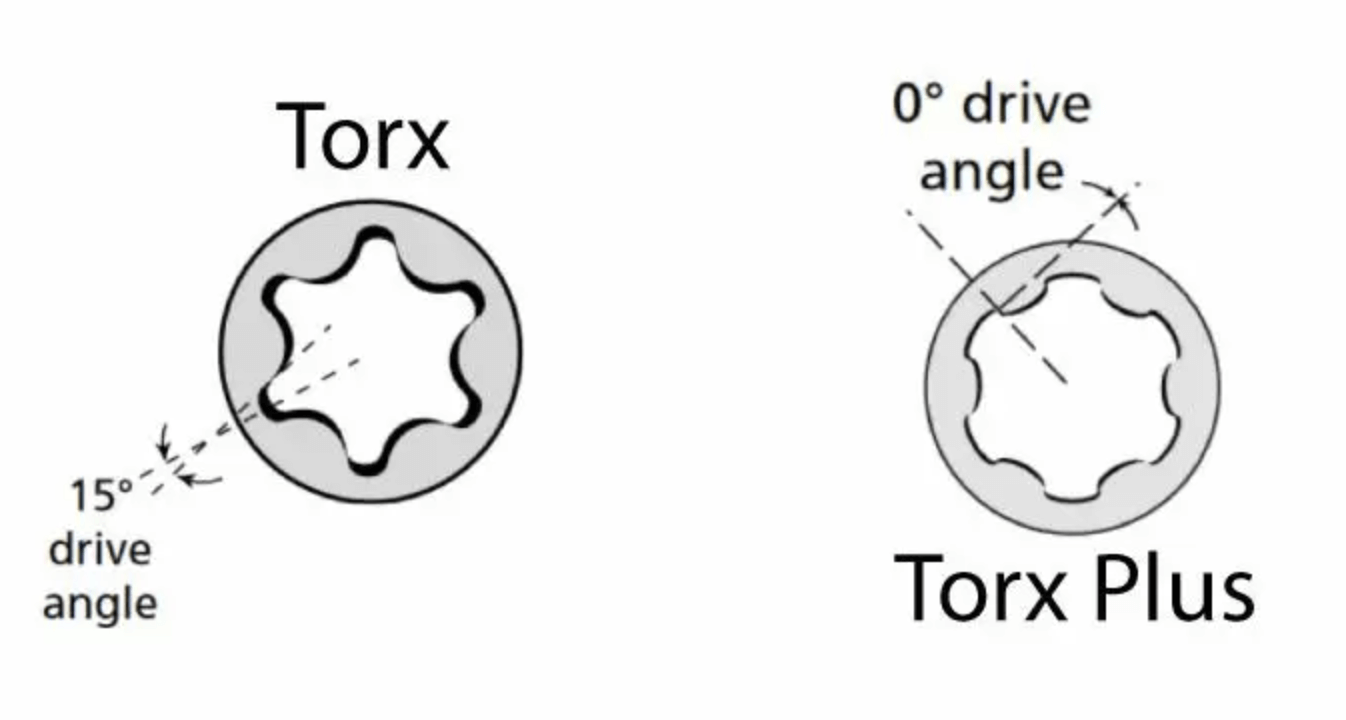

Differences Between Torx and Torx Plus

The primary distinction between Torx and Torx Plus lies in their drive angles and contact points. Traditional Torx feature a 15-degree drive angle, offering excellent engagement but potential for cam-out under extreme stress. Torx Plus, with its 0-degree drive angles, provide increased contact area and minimizes cam-out risk, making it ideal for high-precision CNC tasks.

The Importance of Using the Correct Torque

The Importance of Using the Correct Torque

Applying the correct torque is paramount to prevent damage to both fasteners and tools. Over-torquing can result in stripped screws or broken bits, while under-torquing compromises assembly stability. Precision in torque application ensures the longevity and reliability of both the components and the assembly.

SLOKY’s Torque Tool Sets: Precision and Prevention

SLOKY provides a solution to torque control with its innovative torque tool sets. These sets address this critical issue with preset, adjustment-free torque adapters and a color-coded system for intuitive tool selection. Modular design enables customization to specific needs and budgets, establishing SLOKY as a comprehensive and adaptable solution for torque control in CNC machining.

The Importance of Using the Correct Torque

The Importance of Using the Correct Torque